ISBM College of Engineering

Affiliated to Savitribai phule Pune University Approved by AICTE - Delhi,

DTE - Maharashtra DTE Code : EN6622

To be recognized professional destination in mechanical engineering through providing conductive environment for quality education and research aiming towards techno societal upgradations and technocrats with ethics

To install fundamental knowledge of Mechanical engineering to students through effective teaching learning practices

To develop the spirit of Innovation and Creativity through interdisciplinary research addressing concurrent societal challenges

To promote higher education and enterprising abilities among the students with ethics

Program Outcomes (POs) are statements that articulate what students are expected to know, understand, and be able to do by the time they graduate from the program. These outcomes are aligned with the overall educational objectives of the program and reflect the skills, knowledge, attitudes, and behaviors acquired by students throughout their academic journey. On successful completion of B.E. in Mechanical Engineering, graduating students/graduates will be able to:

| PO No. | Title | Program Outcome Description |

| PO1 | Engineering Knowledge | Apply knowledge of mathematics, natural science, computing, engineering fundamentals and an engineering specialization as specified in WK1 to WK4 respectively to develop the solution of complex engineering problems. |

| PO2 | Problem Analysis | Identify, formulate, review research literature and analyze complex engineering problems reaching substantiated conclusions with consideration for sustainable development. (WK1 to WK4) |

| PO3 | Design / Development of Solutions | Design creative solutions for complex engineering problems and design/develop systems/components/processes to meet identified needs with consideration for public health and safety, whole-life cost, net zero carbon, culture, society and environment. (WK5) |

| PO4 | Conduct Investigations of Complex Problems | Conduct investigations of complex engineering problems using research- based knowledge including design of experiments, modelling, analysis & interpretation of data to provide valid conclusions. (WK8) |

| PO5 | Engineering Tool Usage | Create, select and apply appropriate techniques, resources and modern engineering & IT tools, including prediction and modelling, recognizing their limitations to solve complex engineering problems. (WK2 and WK6) |

| PO6 | The Engineer and The World | Analyze and evaluate societal and environmental aspects while solving complex engineering problems for its impact on sustainability with reference to economy, health, safety, legal framework, culture and environment. (WK1, WK5, and WK7) |

| PO7 | Ethics | Apply ethical principles and commit to professional ethics, human values, diversity and inclusion; adhere to national & international laws. (WK9) |

| PO8 | Individual and Collaborative Team Work | Function effectively as an individual, and as a member or leader in diverse/multi-disciplinary teams. |

| PO9 | Communication | Communicate effectively and inclusively within the engineering community and society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations considering cultural, language, and learning differences. |

| PO10 | Project Management and Finance | Apply knowledge and understanding of engineering management principles and economic decision-making and apply these to one’s own work, as a member and leader in a team, and to manage projects in multidisciplinary environments. |

| PO11 | Life-Long Learning | Recognize the need for, and have the preparation and ability for: (i) independent and life-long learning, (ii) adaptability to new and emerging technologies, and (iii) critical thinking in the broadest context of technological change. (WK8) |

| WK No. | Focus Area | Description |

| WK1 | Natural Sciences and Social Sciences | A systematic, theory-based understanding of the natural sciences applicable to the discipline and awareness of relevant social sciences. |

| WK2 | Mathematics and Data Analysis | Conceptually-based mathematics, numerical analysis, data analysis, statistics and formal aspects of computer and information science to support detailed analysis and modelling applicable to the discipline. |

| WK3 | Engineering Fundamentals | A systematic, theory-based formulation of engineering fundamentals required in the engineering discipline. |

| WK4 | Engineering Specialist Knowledge | Engineering specialist knowledge that provides theoretical frameworks and bodies of knowledge for the accepted practice areas in the engineering discipline; much is at the forefront of the discipline. |

| WK5 | Engineering Design and Environmental Considerations | Knowledge, including efficient resource use, environmental impacts, whole- life cost, re-use of resources, net zero carbon, and similar concepts, that supports engineering design and operations in a practice area. |

| WK6 | Engineering Practice (Technology) | Knowledge of engineering practice (technology) in the practice areas in the engineering discipline. |

| WK7 | Role of Engineering in Society | Knowledge of the role of engineering in society and identified issues in engineering practice in the discipline, such as the professional responsibility of an engineer to public safety and sustainable development. |

| WK8 | Research and Critical Thinking | Engagement with selected knowledge in the current research literature of the discipline, awareness of the power of critical thinking and creative approaches to evaluate emerging issues. |

| WK9 | Ethics and Inclusive Behavior | Ethics, inclusive behavior and conduct. Knowledge of professional ethics, responsibilities, and norms of engineering practice. Awareness of the need for diversity by reason of ethnicity, gender, age, physical ability, etc., with mutual respect. |

To develop graduates with sound technical competency

To inculcate life-long learning and high employability skills

To establish research and development facilities to promote innovations

To generate the spirit of entrepreneurship to create future employers. world.

To promote leadership qualities so as to work and succeed in diverse domains.

Able to apply practical skill, knowledge in the areas of Thermal, Design , Manufacturing and Industrial Engineering

To serve the needs of the society with ethics by pursuing higher studies, taking up the carrier in industries or Govt. Sector.

PhD (Mechanical Engineering)SJJT University ,ME(Design Engineering) Savitribai Phule Pune University, MBA (Operation Management) Savitribai Phule Pune University

MESSAGE FROM HOD DESK

Welcome to the Department of Mechanical Engineering at ISBM College of Engineering, Pune. Over the past decade, we have grown our expertise and competence in the IT enabled Design and Manufacturing centered Mechanical Engineering curriculum and research. Our department offers IT enabled design and manufacturing-based engineering curriculum. The primary focus of our curriculum is to impart technical know-how to students, promote their problem solving skills and innovation of new technologies. Department offers large number of interdisciplinary courses for providing cross cutting knowledge to the students to pursue their interest. The course contents are periodically updated for introducing new scientific and technological developments. Undergraduate students are encouraged to undertake various research projects and encouraged to spend time in neighboring Industries.

Our department has a distinguished record in both teaching and research. Faculty members have excellent academic credentials and are highly regarded.

This website provides an overview of the academic programs, research activities of our department, research facilities, profiles of faculty members, and details of student activities. We hope that whether you are a prospective undergraduate or graduate student, or work in industry, or another university, or a visitor, you will find this website to be informative.

If you have further questions after browsing this website, please do not hesitate to contact us. You may also correspond with individual faculty members, or contact them by email, using the addresses shown on the faculty pages. Our department looks forward to contribute in solving the technological challenges of the society with active participation from all sections of the society. Thank you for visiting us.

| Sr no | Industrial Visit | Date Of Visit | No of Participate | View Document |

| 1 | CARL ZEISS India PVT Ltd | 4 /10/24 | 53 | View Document |

| 2 | Invictous Project Engineers | 16/4/24 | 42 | View Document |

| 3 | Chintamani Motors | 15/4/24 | 38 | View Document |

| 4 | Bhatghar Hydroelectric power Station | 12/4/24 | 13 | View Document

|

| 5 | Katraj Milk Dairy | 28/11/23 | 42 | View Document |

| 6 | Mahindra Sahyadri Motors | 11/05/23 | 34 | View Document |

| 7 | Shri Sant Tukaram Sahakari Karkhana | 26/4/22 | 54 | View Document |

| 8 | CARL ZEISS India PVT Ltd | 28/4/22 | 58 | View Document |

| 9 | Thermal Power Plant Eklahare

|

16/01/2020 | 45 | View Document |

| 10 | Chaskaman Dam Rajgurunagar | 21/08/2019 | 50 | View Document |

| Academic Year | Name of Industry | MOU Date | MOU/Activity Report |

| 2023-2024 | Gouri engineering pvt lt | 5/9/2023 | View Documents |

| 2023-2024 | Aniket Engineering pvt ltd | 10/9/2023 | View Documents |

| 2023-2024 | Vidhvaan com | 28-Aug-23 | View Documents |

| 2022-2023 | Step Up Automation | 4-Mar-22 | View Documents |

| 2021-2022 | Prima Industrial Works | 4-Mar-21 | View Documents |

| 2020-2021 | Salunkhe Enterprises | 8-Mar-21 | View Documents |

| 2019-2020 | Xenstack LLC Pvt Ltd. | 28-Jan-19 | View Documents |

| 2018-2019 | M Cad Solutions training for Excellence | 21-Sep-19 | View Documents |

| 2018-2019 | Blueplant Info Solutions Pvt Ltd. | 18-Jul-18 | View Documents |

| 2018-2019 | Design Tech System Limited | 26-Feb-18 | View Documents |

| 2018-2019 | M Cad Solutions training for Excellence | 5-May-17 | View Documents |

The following documents contains description of the following labs in mechanical department.

| SR. No | LABORATORY NAME |

| 1. | Fluid Mechanics And turbo-Machinery Lab |

| 2. | Heating, Ventilation, Air Conditioning, and Refrigeration (HVAC) Lab |

| 3. | Internal Combustion (IC Engine) Lab |

| 4. | Heat & Mass Transfer Lab |

| 5. | Fluid Power & Control Laboratory |

| 6. | Kinematics of Machinery Lab |

| 7. | Dynamics of Machinery Lab |

| 8. | Mechatronics Lab |

| 9. | Engineering Materials and Metallurgy Lab |

| 10. | Solid Mechanics Lab |

| 11. | Measurement Laboratory |

| 12. | CAD/CAM/CAE Lab |

| 13. | Machine Shop |

| 14. | Thermodynamics Lab |

| 15. | Robotics Lab |

The Fluid Mechanics and Turbo-Machinery Lab offers hands-on experience in fluid dynamics, hydraulic systems, and turbo-machinery. Students explore pressure, viscosity, flow types, pipe losses, and turbine and pump operations through experiments on pressure determination, fluid viscosity, metacentric height, flow visualization, and turbo-machinery principles. The lab also covers cavitation, NPSH, and centrifugal pump characteristics, preparing students for careers in mechanical engineering and power generation.

Features: The FM lab, with a total cost of Rs. 8,42520/- and an area of 66 m², has a key feature focused on turbo-machinery, where students perform hands-on experiments with Impulse Water Turbines, Hydraulic Reaction Turbines, and Steam Turbines. These experiments help students understand the operational principles, performance curves, and efficiency of turbines, providing real-world insights into their role in power generation. This practical experience is crucial for preparing students for careers in energy production and turbine technology.

Utilization : Primarily used by students in Mechanical departments, S.E and B.E, engaged in subjects like fluid mechanics to perform experiments and research work.

Utility of the Lab: Prof. Ashish Z. Ramteke

Lab In-charge: Prof. Ashish Z. Ramteke

The HVAC Lab offers hands-on experience in heating, ventilation, air conditioning, and refrigeration systems. Students engage in practical covering cooling load estimation, ice plant testing, and performance analysis of air-conditioning systems and cooling towers. They also explore the design of cold storage and trial systems like heat pumps, ejectors, cascade systems, and evaporative cooling. These experiments equip students with essential skills in system performance, energy efficiency, and design, preparing them for careers in HVAC, building systems, and refrigeration.

Features: The HVAC lab, with a total cost of Rs. 2,46,500/- and an area of 66 m², focuses on performance analysis and design of HVAC systems. Students conduct experiments on air-conditioning systems, perform cooling load estimations. These practical experiments give students a comprehensive understanding of HVAC system performance, making it a valuable asset for those seeking expertise in system optimization and energy-efficient design.

Utilization: The lab is primarily used by undergraduate students in Mechanical those studying HVAC systems in their final years (B.E) for conducting experiments and research work.

Utility of the Lab: The HVAC Lab, serves the purpose of educating students in designing, maintaining, and optimizing HVAC systems for residential, commercial, and industrial applications.

Lab In-charge: Dr. Sanjay Kumar

The IC Engine Lab provides hands-on experience in internal combustion engines, focusing on performance analysis, efficiency, and fuel characteristics. Students conduct trials on petrol and diesel engines, study fuel consumption, and evaluate engine performance under varying conditions. Key experiments include the Morse Test on a Petrol Engine, performance trials on Diesel and Petrol engines, to analyze its impact on efficiency and fuel economy.

Features: The IC Engine Lab, costing Rs. 7,52,000/- and an area of 66 m², offers hands-on experience in engine performance testing. The experiments on Diesel and Petrol engines are performed, enabling students to study its impact on efficiency, fuel economy, and emissions. These experiments enhance understanding of engine design and optimization, preparing students for careers in automobile, power, and thermal engineering.

Utilization: Primarily used by Second-Year Mechanical Engineering students (S.E.) for the Applied Thermodynamics course to conduct experiments and research in engine technology.

Utility of the Lab: Performance testing of petrol and diesel engines, fuel consumption analysis, and efficiency evaluation.

Lab In-charge: Dr. Sanjay Kumar

The Heat & Mass Transfer Lab offers practical experience in the key concepts of heat conduction, convection, and radiation. Students perform experiments to determine thermal conductivity of insulating powder and metal rods, calculate the heat transfer coefficients in natural and forced convection, and measure the emissivity of test surfaces. Additionally, experiments include determining the Stefan-Boltzmann constant and evaluating the heat transfer, overall heat transfer coefficient, and effectiveness of plate heat exchangers.

Features: The lab, with a total cost of Rs. 4,14,240/- and an area of 66 m², provides students with a comprehensive understanding of heat transfer principles through experiments that involve both theoretical and practical applications. These experiments prepare students for careers in thermal systems, energy, and mechanical engineering.

Utilization: Primarily used by third-year mechanical engineering students (T.E.) for the Heat and Mass Transfer course.

Utility of the Lab: Practical experiments on thermal conductivity, convection, radiation, and heat exchanger performance.

Lab In-charge: Prof. Ravi D. Suryawanshi

The Fluid Power & Control Laboratory provides practical knowledge in hydraulic and pneumatic systems. Students conduct experiments on fluid power control systems, study actuators and their performance in linear/rotary applications, and test various pressure control valves such as relief and sequencing valves. The lab also covers the study of control valves, hydraulic accessories (like accumulators, intensifiers), and electro-hydraulic circuits. In pneumatics, students work with reciprocating, speed control, and electro-pneumatic circuits. Additionally, students design and simulate hydraulic and pneumatic circuits using simulation software.

Features: The lab, with a total cost of Rs. 2,10,000/- and an area of 66 m², offers comprehensive training in fluid power systems. Key features include hands-on experience with actuators, pressure control valves, and hydraulic/pneumatic circuit design. These experiments provide students with essential skills for careers in fluid power technology, automation, and industrial applications.

Utilization: Primarily used by third-year mechanical engineering students (T.E.) for the Fluid Power & Control course.

Utility of the Lab: Practical experiments on hydraulic and pneumatic systems, actuators, control valves, and circuit design.

Lab In-charge: Prof. Ravi D. Suryawanshi

The Kinematics of Machinery Lab offers students practical experience in analyzing and designing mechanical systems. Experiments include speed and torque analysis of epicyclic gear trains, studying the cam jump phenomenon, identifying real-life mechanisms, solving velocity and acceleration problems, designing a planer mechanism using software, and drawing conjugate profiles for gear teeth. Students also conduct kinematic analysis of the Slider Crank Mechanism using Modelling Software.

Features: The lab, with a total cost of Rs. 2,24,480/-, an area of 66 m² offers, students hands-on experience in mechanism design, kinematic analysis, and simulation. These experiments prepare students for careers in mechanical design, robotics, and automation.

Utilization: Primarily used by second-year mechanical engineering students (S.E.) for the Kinematics of Machinery course.

Utility of the Lab: Experiments on mechanism design, velocity and acceleration analysis, and computer programming for kinematic analysis.

Lab In-charge: Prof. Chandrakant Khemkar

The Dynamics of Machinery Lab provides students with hands-on experience in dynamic systems and vibrations. Students perform experiments on dynamic balancing, determine the natural frequency of damped vibrations, and obtain frequency response curves for various damping conditions. The lab also covers torsional vibrations, machine noise analysis, and the gyroscopic effect on a spinning disc. Students simulate the free and total response of damped systems using software to solve differential equations.

Features: The lab, with a total cost of Rs. 1,65,500/- and an area of 66 m², provides hands-on training in dynamic system analysis, vibration testing, and simulation. These experiments equip students with essential skills for careers in mechanical design, machinery diagnostics, and vibration analysis.

Utilization: Primarily used by final-year Mechanical Engineering students (B.E.) for the Dynamics of Machinery course and research work.

Utility of the Lab: Experiments on dynamic balancing, vibration analysis, gyroscopic effects, and system simulation.

Lab In-charge: Prof. Chandrakant Khemkar

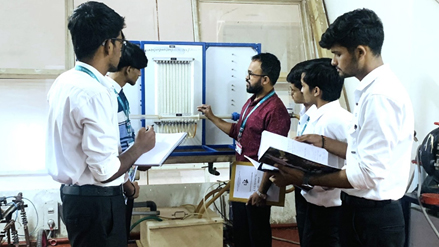

The Mechatronics Lab provides students with practical experience in integrating sensors, actuators, and control systems. Students conduct experiments on temperature, load, and displacement measurement using appropriate sensors, and develop a data acquisition system using open-source hardware and software. The lab also covers sensor-actuator interfacing with DAQ, modeling and analysis of mechanical systems, and PID control using simulation software, followed by experimental verification.

Features: The lab, with a total cost of Rs. 3,53,532/- and an area of 66 m², equips students with skills in mechatronics system design, sensor integration, and control system analysis, preparing them for careers in automation, robotics, and control engineering.

Utilization: Primarily used by Third-Year Mechanical Engineering students (T.E.) for the Mechatronics course.

Utility of the Lab: Experiments on sensor measurements, mechatronics systems, PID control, and simulation.

Lab In-charge: Prof. Ashish Z. Ramteke

The Engineering Materials and Metallurgy Lab provides students with hands-on experience in material testing and analysis. Students perform destructive tests like hardness testing (Rockwell/Vickers), impact tests on materials like steel, aluminum, brass, and copper, and conduct non-destructive tests such as dye penetrant, magnetic particle, and ultrasonic tests. The lab also includes specimen preparation for microscopic examination and observation of the microstructure of steels, cast irons, and non-ferrous metals.

Features: The lab, with a total cost of Rs. 44,12,000/- and an area of 66 m², provides essential training in material characterization, microstructural analysis, and testing techniques, preparing students for careers in materials science, metallurgy, and quality control.

Utilization: Primarily used by Second-Year Mechanical Engineering students (S.E.) for the Engineering Materials and Metallurgy course.

Utility of the Lab: Experiments on material testing, microstructure analysis, and non-destructive testing.

Lab In-charge: Prof. Tushar V. Edake

The Solid Mechanics Lab provides second-year students (S.E.) with practical experience in material testing and stress analysis. Students perform tension, compression, and shear tests on materials using the Universal Testing Machine, test plastic/composite materials with a low load tensile machine, and verify flexural and torsion formulas for beams and circular bars. The lab also includes stress distribution pattern analysis using a Polariscope and verification of experimental results with FEA software.

Features: The lab, with a total cost of Rs. 3,65,625/- and an area of 66 m², focuses on material testing and stress analysis using both experimental and computational methods, preparing students for careers in structural engineering, materials testing, and finite element analysis.

Utilization: Primarily used by Second-Year Mechanical Engineering Students (S.E.) for the Solid Mechanics course.

Utility of the Lab: Experiments on material testing, stress analysis.

Lab In-charge: Prof. Tushar V. Edake

The Measurement Laboratory offers students hands-on experience in measurement techniques and calibration. Students learn load cell and dial gauge calibration, perform linear and angular measurements, study limit gauges, and Taylor's principle. The lab also includes experiments on surface roughness, geometry determination using a Toolmakers' Microscope, and verifying components with a mechanical comparator. Additionally, students determine modulus of elasticity using strain gauges and work with Gear Tooth Vernier Calipers.

Features: The lab, with a total cost of Rs. 61,50,78/- and an area of 66 m², offers a comprehensive understanding of measurement techniques, calibration, and precision instruments, essential for students pursuing careers in quality control, manufacturing, and metrology.

Utilization: Primarily used by Third-Year Mechanical Engineering students (T.E.) for the Measurement course.

Utility of the Lab: Focuses on measurement techniques, calibration processes, and precision instrument usage.

Lab In-charge: Prof. Tushar V. Edake

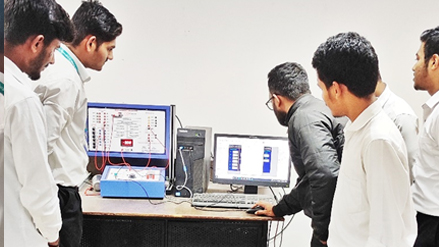

The CAD CAM CAE Lab integrates multiple subjects including Solid Modeling and Drafting, Computer Aided Engineering (CAE), AIML, Data Analytics, and Computer Integrated Manufacturing (CIM). The lab is equipped with dedicated computers and relevant software to provide students with practical exposure to computer-aided design, simulation, analysis, and manufacturing. Experiments cover a wide range of topics, including 2D sketching, solid and surface modeling, assembly modeling, reverse engineering, data analysis, and machine simulation.

Features:

Utilization: The lab is utilized by students across various levels (S.E., T.E., and B.E.) for subjects in Solid Modeling, AIML, CAE, Data Analytics, and CIM and research work

Utility of the Lab: The lab serves as a platform for students to gain practical skills in designing mechanical components, simulating mechanical systems, performing structural and thermal analysis, and understanding manufacturing processes. It also helps students develop expertise in data-driven methods such as machine learning and data analytics.

Lab In-charge: Prof. Nitin P. Bahiram

The Machine Shop provides practical training to students from First Year Engineering (FE) to Final Year B.E. (Mechanical) in various manufacturing processes. The shop is equipped with a wide range of tools and machines for cutting, welding, machining, and advanced manufacturing techniques. Experiments include operations on conventional machines like lathe, drilling, milling, and CNC, as well as modern techniques like additive manufacturing and composite materials processing.

Features:

Utilization: The lab is utilized by F.E. students and Mechanical Engineering students for practical sessions on basic and advanced manufacturing processes, including machining, welding, CNC programming, and additive manufacturing.

Utility of the Lab: The lab provides hands-on experience in various manufacturing processes such as turning, milling, grinding, welding, and CNC machining. Major experiments include CNC part programming, additive manufacturing, plastic molding, and the design of jigs and fixtures.

Lab In-charge: Prof. Nitin P. Bahiram

The Thermodynamics Laboratory offers students hands-on experience in understanding the principles of energy conversion and thermodynamic processes. Students conduct experiments to determine the higher calorific value (HCV) of solid and gaseous fuels, demonstrating the efficiency of various fuels in energy production. The lab also includes the use of the Orsat apparatus for gas analysis and methods for determining the dryness fraction of steam. These experiments help students gain a solid understanding of thermodynamic cycles and the application of thermodynamic principles in real-world energy systems.

Features: The lab, with a total cost of Rs. 4,26,882/- and an area of 66 m², provides essential training in thermodynamics-Engineering and Applied Thermodynamics. Students engage in practical work to determine fuel properties, analyze combustion processes, and assess steam quality. The lab’s facilities foster in-depth understanding of energy systems, making it an invaluable resource for students pursuing careers in energy, mechanical engineering, and related fields.

Utilization: Primarily used by second-year mechanical engineering students (S.E.) for the Thermodynamics course. It is also utilized by students for research projects involving energy systems, fuel analysis, and thermodynamic applications.

Utility of the Lab: Practical experiments on the determination of the calorific value of fuels, gas analysis using the Orsat apparatus, and dryness fraction determination which are critical for understanding thermodynamic cycles, energy efficiency, and fuel properties in real-life applications.

Lab In-charge: Prof. Ravi D. Suryawanshi

The Robotics Lab at our institute is a state-of-the-art facility designed to inspire and train future engineers in the field of robotics and automation. It offers students a platform to gain hands-on experience with various robotic systems and automation technologies, bridging the gap between theoretical knowledge and industrial application. The lab is equipped with the latest technology, encouraging innovation and creativity among students.

Features: The Robotics Lab covers 66 square meters, offering space for collaborative projects and hands-on experiments. It features robots, automation systems, and tools for building robots for domestic and commercial use. The key features being, platforms like Arduino Uno, Arduino Nano, ESP8266, and Raspberry Pi, enabling students to work on diverse projects. This combination of resources supports technical learning and skill development in robotics and automation.

Utilization: The lab is primarily used by students from mechanical, electrical, and computer science engineering backgrounds, but is also open to those interested in robotics, automation, and IoT. It serves as a space for faculty and industry experts to hold workshops, training, and collaborative projects. Projects Done till Date: Ultrasonic Radar, Bluetooth RC Car, Keypad Shield Games, Robot Arm (Open Computer Vision Library), Earthquake detection system, Helmet detection system (Open Computer Vision Library), Petrol Purity detector

Utility of the Lab: Undergraduate students work on projects to gain practical experience in robotics and automation, enhancing skills in mechanical design, programming, system integration, and problem-solving. Current projects include obstacle avoidance robots, smart lighting systems, and IoT weather stations.

Lab In-charge: Prof. Sachin S. Jadhav

| Sr. No. | Department | Class | Name of student | SGPA | Rank | Photo |

|---|---|---|---|---|---|---|

| 1 | Mechanical | SE | INGLE YOGESH NILKANTH | 8.64 | 1st |  |

| 2 | Mechanical | TE | PALANGE SURYANSHU KAILASH | 7.98 | 1st |  |

| 3 | Mechanical | BE | MULAM MAYURESH PRAKASH | 8.37 | 1st |  |